ENGINEERING

Product Introduction

Design for Manufacturability (DFM) is a well-efficient tool to help product designers to minimize developing costs, drawing error, and time from market design concept phase to mass production stage. Pyramids Technology specializes in various of plastics injection and offering free DFM service with comprehensive report that covers the details of mold concept, mold flow, expectations for the build, and final DFM recommendations on your injection molding projects. This allows our customers to take advantage of keeping designs development as simple as possible while keeping costs to minimum.

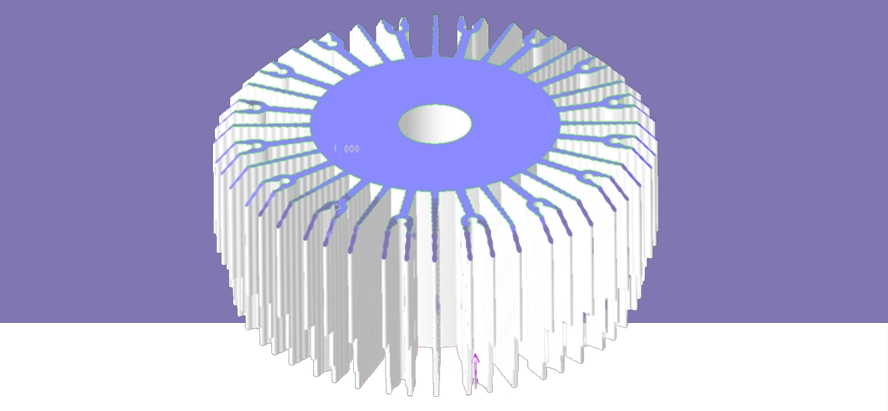

- Mold Concept illustration

- Drawing Analyzing

- Gating optimization.

- Part Feature Evaluation.

- Undercuts recognizing and elimination.

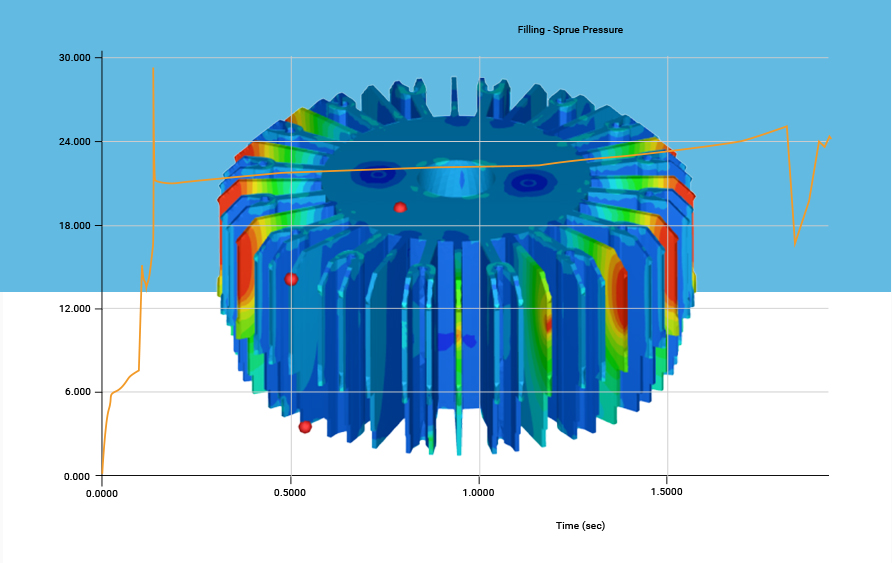

- Mold Flow Analysis

- Out Come Prediction

Pyramids Technology applies cutting edge systematic scientific molding principles to control and optimize the key factors during the actual injection process, such as flow rate, mold temperature, melt temperature, filling pressure, packing pressure, etc. In order to analyze and interpret a process window for consistency, reliability, and repeatability.

- Consistency, precision, and qualification

- Yield rate and circle time optimization.

- Higher efficiency and less defection molding process window.

- Cost saving for development, materials consumption, and production.

- Prevent or minimize potential quality issues.

- Fill time and peak pressure in velocity control.

- Viscosity and pressurization

- Constantly pressure hold and the time of which.

- Injection and cavity pressure record analysis.

- Pressure lose study

- Cavity balance

- Gate sealed.