Quality

Quality assurance and customer satisfaction are what Pyramids plastic injection molding manufacturers always pursue with continuous development innovations and production improvement. We established a solid quality management system and process including supplier evaluation, incoming quality inspection, in-process quality control, and reliability testing to support our production process and standard requirement. We are determined to provide the best medical plastic injection molding service to customers, and below are certifications, equipment, etc we possess.

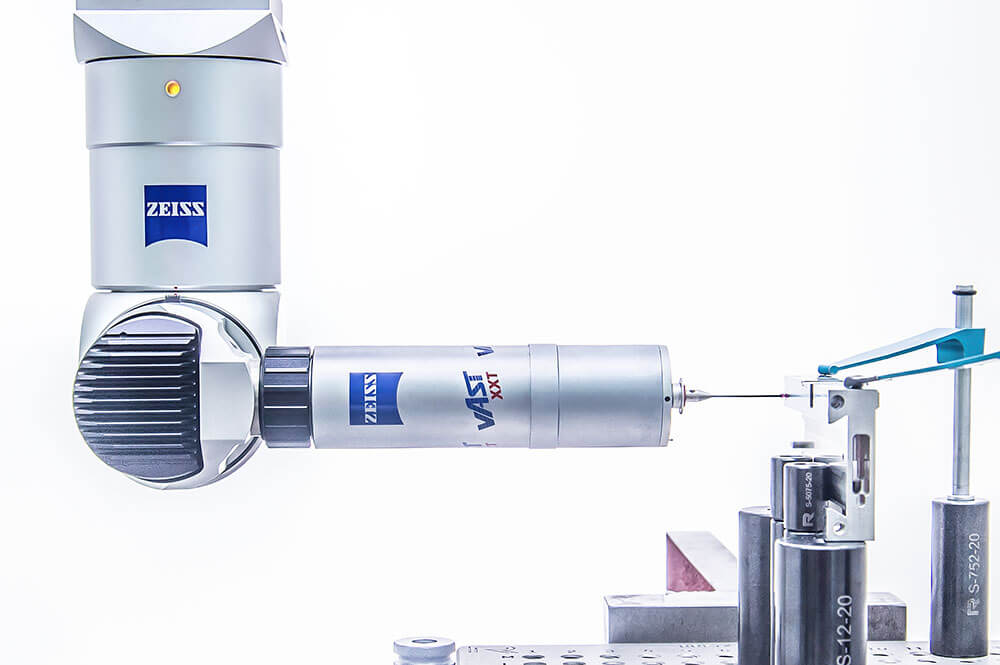

- ZEISS CMM

- ISO Class 7 standard Clean room

- ISO Class 8 standard Clean room

- 2.5D Optical Comparator

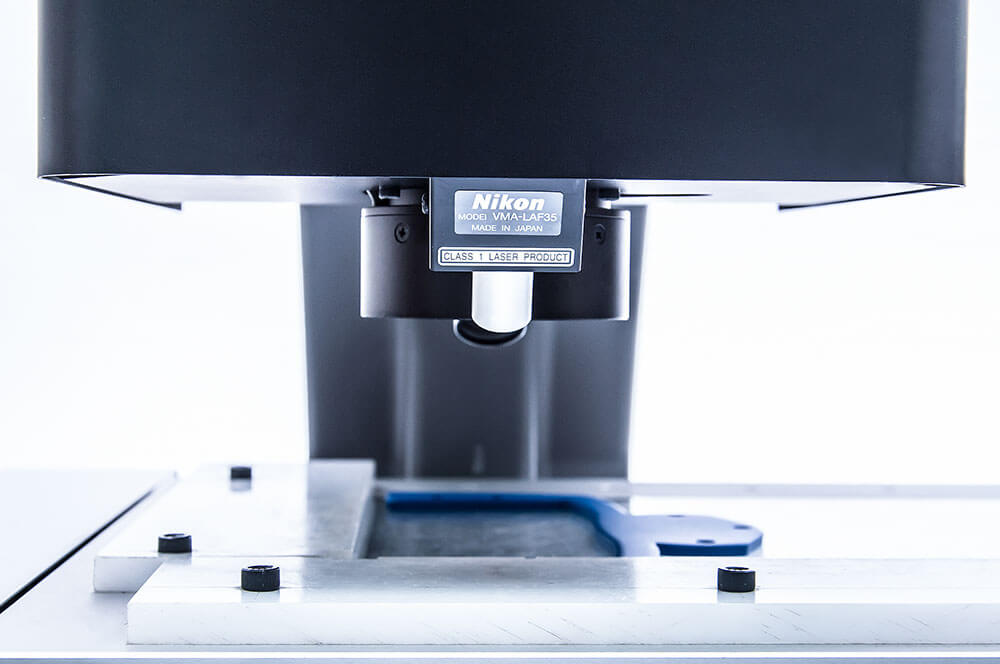

- Nikon 2.5D CNC Optical Comparator

- Konica Photoelectric Spectro colorimeter (Color-difference meter)

- Handheld XRF Analysis

- Mitutoyo Surface Roughness Tester

- MI Melt Index

- Tensile Testing Machine

- Positector Film Thickness Gauge

- Mitutoyo Hardness Testers

- Environment control room with Temperature & Humidity testing

Pyramids precision medical machining company follows the GD&T system standard to define the engineering design deviation tolerance and assure the degree of accuracy is controlled well and truly understands the clients’ intent.

GD&T can be used to communicate the functional requirements precisely for the size, location, orientation, and shape of the design with benefits of:

- Standardization for design and engineering development.

- Accurate and appropriate definition for inspection plan.

- Eliminates complicated notes especially for complex shapes.

- More flexible tolerance allowance for a better cost.

- Subsequent inspections can be measured against.

Pyramids Technology cleanroom assembly company implements GD&T to establish and simplify an agreed-upon inspection standard in form and the size of individual features to define features variation and ensuring design, production, and inspection are all working in the same unified specification.

Pyramids Quality Assurance Testing Plan includes

- Inspection system from IQC, IPQC, OQC, and FAI

- AQL

- Gauge Calibration implementation and management.

- Reliability control and statistical defect analysis

- Abnormal and rework management

- AVL (Approved Vendor List) quality management

- Periodical vendor rating and review.

- Staffs QA training program for continual improvement

- IQ, OQ, PQ Validation system.