Aluminum Extrusion

Product Introduction

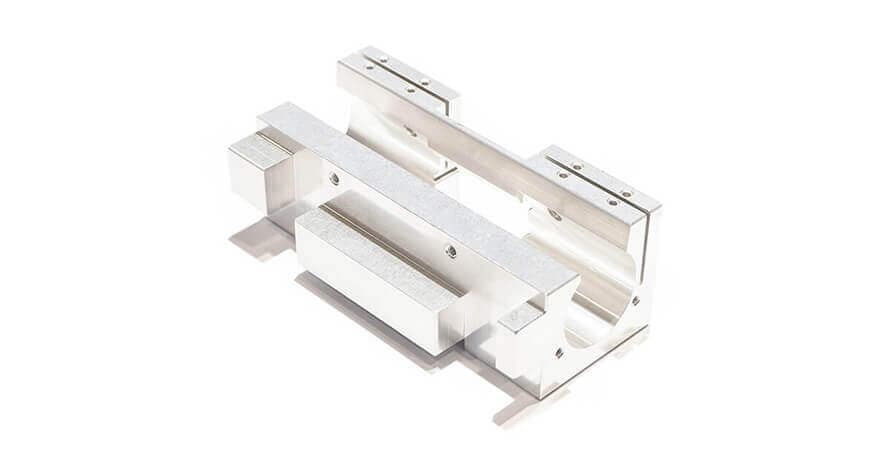

Custom Aluminum Extrusion Services

Extrusion refers to the process to create complex, fixed cross-sectional products in the manufacturing industry. Among the materials available, aluminum is considered one of the best substances for extrusion as it has exceptional elasticity and aluminum extrusions offer designers and manufacturers the choice of features such as light, strong, rust-proof, and attractive surfaces. Aluminum has a relatively lower cost than other metals or alloys. This practice is best suited when a customer requires products with cross-sectional features at a reasonable cost. With aluminum extrusion, the strength of the aluminum alloy can be easily enhanced, and the target area can be reinforced with ease. The extrusion process can be easily tailored, and the product can be conveniently assembled and fabricated. Aluminum is also highly sustainable as its properties have little to no degradation and can be easily recycled, further reducing the cost and improving the environment. Custom aluminum extrusion is also a trend in recent years as it meets customers' specific needs directly. As leading aluminum extrusion suppliers, Pyramids Technology can meet customers' different demands.

Aluminum Extrusion Process

The fundamentals of aluminum extrusion are relatively easy, aluminum is pushed through a die and comes out from the other end shaped like the die itself. To understand it better, we must follow through with the detailed process. A solid aluminum pillar commonly known as a “billet” will be heated to the desired temperature to turn it into a soft solid. Once it is ready to enter the die, lubricant will be administered to the ram and billet to prevent them from sticking together. Then, the ram will apply pressure to the billet to push it through the die, turning the billet into the desired shape and form. A second billet is added and welded to the current one and the process continues. The extrusions that are pushed out will be cut once it reaches the desired length, and the metal will be guided onto a cooling table to be cooled off and then to the stretcher to be work-hardened (metal hardened by a physical process), later on, cut into selected lengths. Lastly, it will be sent into the aging oven to speed up the metal aging process, then the product can be sent to be finished or fabricated.

Aluminum Extrusion Companies

So, why should you choose aluminum for extrusion? Aluminum extrusion is known for its great lead time and cost-efficiency. Besides that, its property is highly versatile and offers multiple benefits compared to other materials. Aluminum isn’t as dense as other metals such as copper, iron, or steel, which makes aluminum the primary candidate when it comes to weight-limited applications, and makes handling and shipping easier. With aluminum extrusion, the strength of the aluminum alloy can be easily enhanced, and the target area can be reinforced with ease. It is also an excellent thermal and electrical conductor while being non-sparking and non-toxic. The extrusion process can be easily tailored; the product can be conveniently assembled and fabricated. Aluminum is also highly sustainable as its properties have little to no degradation and can be easily recycled, further reducing the cost and improving the environment.

Our Aluminum Alloy Die Casting Processing Capabilities

Aluminum extrusion is a common metal manufacturing process, but factors such as temperature, extrusion speed, extrusion ratio, and finishing will greatly affect the result of the product. Pyramids Technology provides the service of aluminum extrusion design, manufacturing, fabrication, powder coating, or anodizing, and also performs secondary operations like cutting, punching, welding, and further CNC machining. The versatility and potential of extrusion technology are limitless, and our company applies this technology to provide a customized, streamlined, and high-quality service for our customers. We provide a high-quality product that will satisfy our customer’s needs, tailor service for our customer’s requirements, and develop prototypes that will transform your concept into reality. Quality, efficiency, and service are our company motto, and we will please our customers within our power. Please contact Pyramids Technology aluminum extrusion manufacturers for assistance in optimizing your aluminum extrusion application.